.jpg)

Engineering students aim to fly high in national competition

A group of Engineering degree students at the University of Wolverhampton are hoping to fly high in a major competition being held later this month which has tasked them with building an aircraft!

The five students are studying for Aerospace Engineering and Mechatronics Engineering degrees at the University’s Telford Innovation Campus and have formed the Wolverhampton Aerospace team (UWA) to compete in the Institution of Mechanical Engineers (iMeche) Unmanned Aerial System (UAS) Challenge Competition being held at the British Model Flying Association’s Buckminster site on 27-29 June.

The Fly-Off event, which takes place annually in June, marks the grand finale of the preceding nine months during which dedicated student teams design, construct, and pilot a fully-autonomous Unmanned Aerial System (UAS) for humanitarian aid missions.

During the fly-off event, teams will have the opportunity to showcase their design and engineering skills by delivering formal presentations of their UAS before a panel of senior engineers from across the aerospace industry. Additionally, teams have the chance to demonstrate the capabilities of their UAS, further emphasising the technical achievements of their crafts during live events.

Edward Green, Project Manager for UWA and studying for an Aerospace Engineering degree, said: “We’re really looking forward to taking part in the competition later this month. The aim of the challenge is to design and manufacture an aircraft from scratch to complete a series of tasks such as a payload drop. This is to simulate a disaster relief scenario. The challenge is open to all universities which allows us to compete on a global scale.

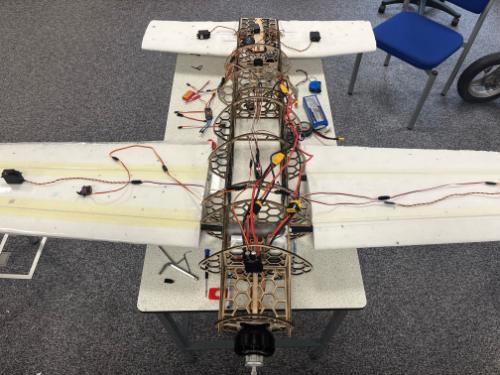

“We are just a small team made up of Aerospace and Mechatronics students who have teamed up over the last year to build the aircraft. The aircraft features a laser cut plywood internal structure with a 3D printed skin made from lightweight PLA. The wings, stabilisers and rudder are made from foam and then wrapped in fibreglass. A cool thing about the manufacture of the wings is that we also built the machine which made the wings. The machine is made from two old 3D printers which were used to manufacture PPE during covid. Once they became unserviceable as 3D printers, we took the time to service them and rebuild them into a fully functioning CNC hot wire cutter.

“Lastly, the aircraft also uses a pixhawk system. A pixhawk system is a flight controller and gps system which enables the aircraft to have autonomous flight. This system is completely programmable and will enable the aircraft to fly on its own without human intervention.”

The team is utilising the industry standard manufacturing equipment at Telford Campus to shape their design.

Dr Aman Dhir, Head of Engineering at the University, said: “It’s vital that our students get hands-on, real-world experience to complement their learning and competitions like this one are ideal for them to really show off the skills they have learned during their studies.

“The team is working hard to prepare for the competition and they are really using their initiative, repurposing equipment and doing lots of research to help them in their quest. We all wish them the very best of luck in the competition.”

The team recently showcased their work at the RAF Cosford Air Show. The Engineering students involved are Edward Green (Aerospace) Alex Byrne (Mechatronics), Dawid Redmann (Aerospace), Valerio Williams, (Aerospace), Ikemefuna Collins Nwanze (Aerospace) with support from lecturer, Dr Graham Sparey-Taylor.

Anyone interested in courses being offered should check out the website or register for one of our forthcoming Open Days.

ENDS

For more information please contact the Corporate Communications Team.

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/Diane-Spencer-(Teaser-image).jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-18-19/220325-Engineers_teach_thumbail.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/241024-Dr-Christopher-Stone-Resized.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/UoW-City-Campus-(Teaser-Image).jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/241014-Cyber4ME-Project-Resized.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/240315-Research-Resized.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/WMCA-event-(teaser).jpg)

.jpg)

.jpg)